FAQs

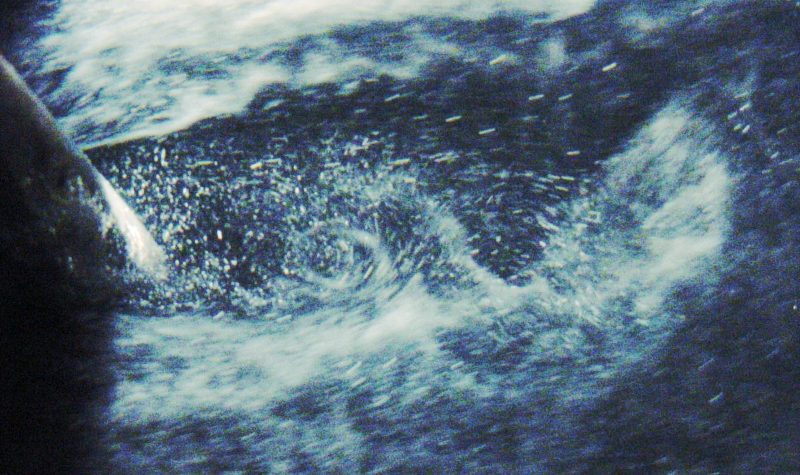

Vortex-Induced Vibration (VIV) can occur on offshore cylindrical structures.

VIV can result in:

- Fatigue damage

• Drag amplification (up to a multiple of 3.0 on the global drag force)

Offshore riser and pipeline systems can experience the following types of Vortex-Induced Vibration as a function of the reduced velocity, Vr, parameter:

Vr < 4

• Pure In-line VIV response with amplitude ~ 10-15% of diameter.

This type of response is normally only examined for pipeline or rigid spool freespan response

Vr > 4

• Cross-Flow VIV vibrations with amplitudes up to 1.5 times diameter and potentially significant drag amplification effects (This type of response is normally examined for long dynamic cylindrical structures such as riser systems, TLP tendons, cables).

• In-line associated response driven by the Cross-Flow with vibration amplitudes less than the Cross-Flow amplitudes

VIV becomes more likely to occur when there are high shedding frequencies present, such as with:

- Higher current velocities

• Smaller diameter cylinders

Or when the natural frequencies of the structure are lower, such that they can be excited by the shedding frequency, these occur with:

- longer structures

- lower tension

To be confident whether or not VIV will occur, simplified approaches can be used, one such simplified approach is described in DNV RP F204 Riser Fatigue Section 4.

The industry has been grappling for many years on the issue of what is the best selection for the fatigue factor of safety to use for VIV design. Typically, the uncertainty in VIV prediction is greater than other sources of dynamic excitation, as VIV is a highly non-linear complex phenomenon. Where certainty in prediction is much more reliable, for other dynamic responses, safety factors as low as 3 are used. The industry has to date dealt with the larger uncertainty in VIV prediction by applying fatigue safety factor multiples such as 10 or 20, but with no rational basis. In some cases there is already enough over-prediction bias present that such large factors are not necessary to meet the industry targeted annual probabilities of failure like 10-5.

Studies led by AMOG and championed by DeepStar that dealt with this issue. For details on the results of these studies, please refer to the paper OMAE2011-49820 “Reliability Based Factors of Safety for VIV Fatigue Using NDP Riser High Mode VIV Tests” by Fontaine, E., Marcollo, H., Vandiver, J.K., Triantafyllou, M., Larsen, C.M., Tognarelli, M., Constantinides, Y., and Oakley, O.H.

Yes. A new set of SHEAR7 specific modelling parameters based on model tests has been generated for this purpose. These will be formalized in the next update of the program but are available for use with the existing version.

Triple start helical strakes with 100% coverage over the length of the riser having a geometry of 0.25/17.5 D (height/pitch as a function of diameter) have been shown in model tests to be very effective. In real applications, these strakes may become damaged and suffer from marine growth, particularly in the upper part of the water column. Assessment for the performance of the riser should be made by looking at the sensitivity to overall fatigue when the effectiveness of these strakes is reduced.

Global drag amplification due to VIV is one of the most important physical effects of VIV. The drag amplification is dependent on the amplitude of vibration and will occur whenever VIV occurs. One of the key outputs from SHEAR7 is its able to predict the drag amplification to be applied to the base drag coefficient on the structure.

SHEAR7 requires steady state current profiles as input. In the cases of expected substantial wave induced excitation, for example when KC>40 (where KC is the Keulegan-Carpenter number), the wave profiles can be superimposed on any background current profiles. For conditions where KC is less than 40, there are still circumstances where superimposing wave and current is an adequate analysis approach. When KC is very small, there are other prediction methods which are more appropriate. Please contact user support to discuss.

The level of ‘binning’ of the current profiles requires engineering judgment, however as SHEAR7 is a frequency domain program and runs extremely fast, then there is no real time penalty for choosing finer levels of discretization. For near vertical structures, the current should always be made omni-directional, for structures which are not near vertical, such as SCR’s, the user may decide different approaches to resolving current directionality.

SHEAR7 offers a higher fidelity inline VIV response prediction than DNV-RP-F105. DNV-RP-F105 prescribes an amplitude but makes no comment on the relationship between the amplitude and its value in a modeshape, whereas SHEAR7 uses measure in-line VIV force lift curves to iterate and include modal shape effects to estimate total response.

SHEAR7 is a mode superposition program that works in the frequency domain. It is applicable to any structure that responds with modeshapes. For realistic ocean structures with some complexity, it is often advisable to have the natural frequencies and modeshapes input from a 3rd party modelling program like Orcaflex, Flexcom, RIFLEX, Abaqus, ANSYS, for example. AMOG understand that not all of these programs come with automatic export to SHEAR7 functions so, for some programs, users will need to write their own. AMOG can do these conversions, for a fee. Please contact SHEAR7 for more information.

For complex situations, the structural model should be prepared in a 3rd party software. The hydrodynamics of in-line VIV excitation is not very well understood in the presence of boundaries. Cross-flow VIV response prediction is better understood. SHEAR7 is a frequency domain analysis tool. If non-linear time domain soil interaction is important and necessary, other tools should be investigated.

SHEAR7 training is offered in Houston and, from time to time, other locations. Information on these training sessions are posted on this site and also emailed to the SHEAR7 Usergroup. Please ensure that your details are up to date and contact SHEAR7 if you have any questions. If you are interested, training can be arranged locally, for a fee.

In-line and cross-flow vibrations are treated differently depending on what reduced velocity regime and what mode number regime the user is in. For pure first mode in-line VIV response, SHEAR7 treats the excitation as in-line only. In terms of high mode number response, any in-line VIV response is treated as associated to the dominant cross-flow response and considered to be of equal magnitude to the cross-flow fatigue damage rate.

SHEAR7 is a mode superposition program. Provided with the natural frequencies (and modeshapes), it can be used to screen as well as calculate VIV fatigue. Since it is a frequency domain program, it is very fast. Some users utilise it to screen for the onset of VIV in pipelines as well as risers/conductors.

If the user has a structural model in a third analysis package then modeshapes and natural frequencies can be imported into SHEAR7. For some structural model packages, a small pre-processor may be required to be written to convert to SHEAR7 format. Please check with the structural model distributor.

The software’s forte is dealing with sheared currents. To assess, the user is required to input quasi-static representations of the current + wave velocity profiles.

The output may be “No VIV is predicted to occur.” Or there will be VIV and results provided, which will include all the standard results you would expect (amplitudes, frequencies, curvatures, fatigue estimates etc.)

It is listed in the output file as results by mode number and combined results.

Yes. SHEAR7 incorporates in-line VIV prediction. This will work the same way as the cross-flow described above in terms of screening and results

The stick-slip damping feature has been added into SHEAR7 to take into account potential additional structural damping due to interlayer friction dissipating energy. This feature is most applicable to unbonded multi-layered structures like dynamic power cables, static cables with large spans on the seabed subject to VIV, dynamic umbilicals and dynamic flexible unbonded risers (it is not applicable for homogeneous steel pipe). The program incorporates sets of bending stiffness versus curvature hysteresis curves, which are generally a function of tension. If the user does not have a hysteresis curve it may be possible to hand calculate one.

The Strouhal number depends on a number of factors including the direction of vibration (in-line vs cross flow VIV), whether the cylinder is fixed or freely vibrating and the Reynolds number. SHEAR7 is validated against experiments ranging between 0.15 to 0.25 however. A relevant paper on Strouhal numbers is OMAE2018-51241.